On Feb. 22nd, cooperation research result of Assoc Prof. Jiabin Liu, Prof. Hongtao Wang(Zhejiang University), Prof. Dierk Raabe(Max Planck Institute, German), Nonbasal slip systems enable a strong and ductile hexagonal-close-packed high-entropy phase, was published on Physical Review Letters.

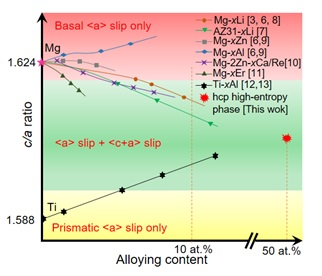

HCP metals, such as Mg, Ti, etc., have unique physical, chemical, and mechanical properties, and are of great importance on technology and society. Among them, Mg is called the most promising engineering materials in the 21st century because of its abundant storage, low density and high strength. However, traditional HCP metals have worse plasticity because of its less slippage system, compared with FCC and BCC metals, which limits its manufacturing. Available slippage systems of HCP metals are closely associated with the axe of its lattice structure. For larger axes, such as Mg and Zn, inner dislocations mainly locate on case facet. For smaller axes, such as Ti and Zr, inner dislocations mainly locate on cylinder facets. Previous research demonstrated that appropriate additional alloy elements can effectively adjust axial rate of HCP metals. In traditional alloy designs, the concentration of solute is limited, so the axial rate is less regulated. The design idea of high-entropy alloy breaks the single element of traditional alloy and contains many main elements. The concentration of alloying elements is much higher than that of traditional alloys, which significantly expands the control range of HCP axial ratio. The research team found that the HCP phase of Fe50Mn30Co10Cr10 high-entropy alloy showed good plastic deformation ability. X-ray diffraction results showed that the axial ratio of the HCP phase was significantly lower than the theoretical value. Through in-situ tensile experiments by transmission electron microscopy, it was found that the dislocation motion of the cone-slip system is active during the deformation of the HCP phase. Based on a large number of transmission electron microscopy characterizations, up to 31% of non-base facet dislocations were counted in the HCP phase.

Based on the alloy design method, it is expected to use the high-entropy alloy idea to greatly adjust the axial ratio of the traditional HCP metal, and develop a new HCP alloy with high toughness and high forming ability.

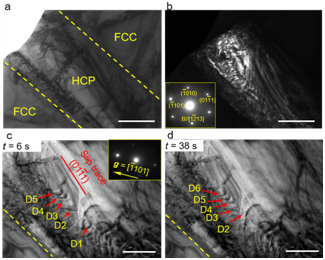

Fig.1 Characterization by in situ transmission electron microscopy showing that non-base surface dislocation slip in the HCP phase is activated.

Fig.2 Characterization by ex situ transmission electron microscopy showing the presence of a large number of non-basal plane dislocations in the HCP phase.

Fig.3 Compared with traditional magnesium and titanium alloys, it is shown that the high entropy HCP phase has a large adjustment of the axial ratio due to its high solute concentration, which is in the region capable of exciting multiple slip systems.

Yeqiang Bu, PhD. candidate of our school and Zhiming Li, PhD. candidate of Max Planck Institute are the co-first authors. Assoc. Prof. Jiabin Liu of our school, Prof. Hongtao Wang of Zhejiang University and Prof. Dierk Raabe of Max Planck Institute are corresponding authors. Academician Wei Yang of Access Cross Mechanics Center is also on of the co-workers.

This research was supported by National Natural Science Foundation and Central College Fundamental Research Fund.